(LPC) Testing

Liquid Particle Count

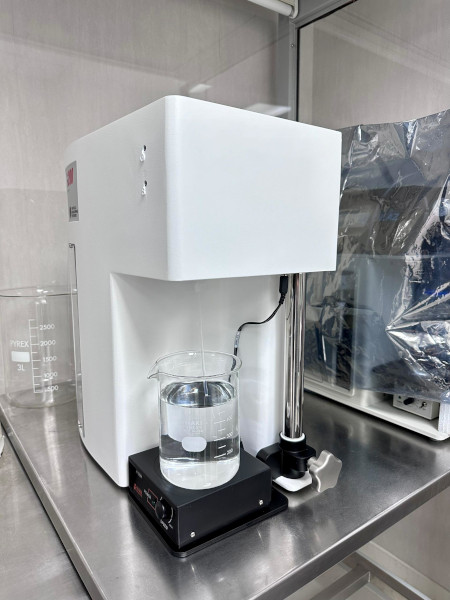

Our Electric & Electronics ServicesLiquid Particle Count (LPC) testing is a method employed to quantitatively assess the concentration and size distribution of particles suspended within a liquid sample.

This analytical technique involves the use of specialized instruments, such as particle counters or analyzer, capable of detecting and measuring particles within the liquid medium. The testing process typically entails the collection of liquid samples followed by analysis using these instruments to determine the number and size of particles present per unit volume of the liquid.

The Importance of SVHC Testing

Industries across various sectors, including pharmaceuticals, biotechnology, semiconductor manufacturing, and food and beverage production, rely on Liquid Particle Count (LPC) testing to ensure product quality, safety, and compliance with regulatory standards. This testing is critical for maintaining the purity and integrity of liquid products and processes.

In pharmaceutical and biotechnology industries, for instance, particles in liquid formulations can pose risks to patient safety and product efficacy. Contaminants such as glass shards, fibers, or microbial particles can compromise the quality and safety of injectable drugs, intravenous solutions, or other liquid pharmaceutical products.

Therefore, rigorous testing protocols are implemented to detect and quantify particles in these formulations, ensuring adherence to regulatory requirements and industry standards.

SVHC Testing in BIOCHEM

BIOCHEM has the capability to support you in ensuring product integrity, optimizing processes, controlling contamination, mitigating risk and achieving regulatory compliance across a diverse range of industrial applications. This helps safeguard the safety and satisfaction of your customers.

Get In Touch

Looking to discuss your needs or get a quote from our electrical safety testing experts? Contact us today!